A Different Concept For Building The Great Pyramid |

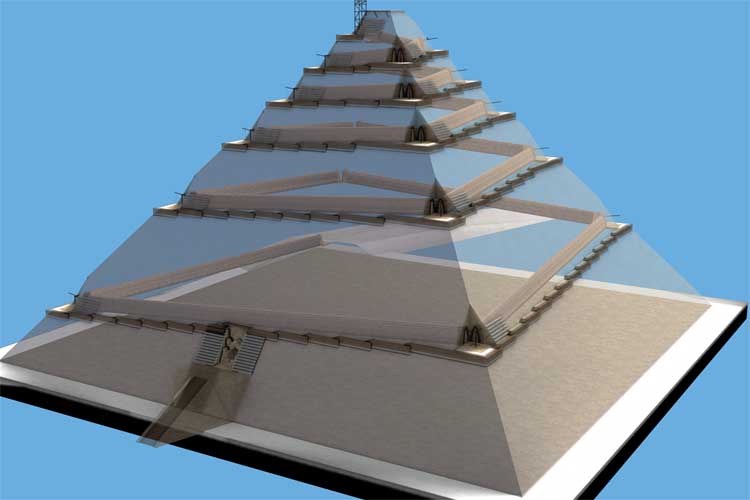

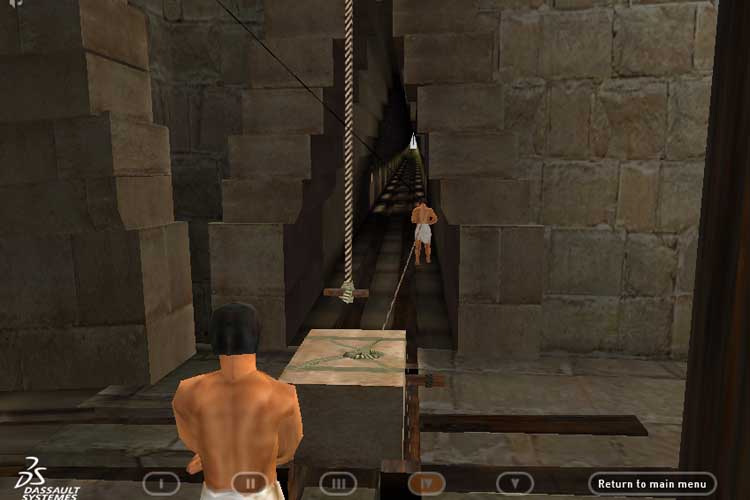

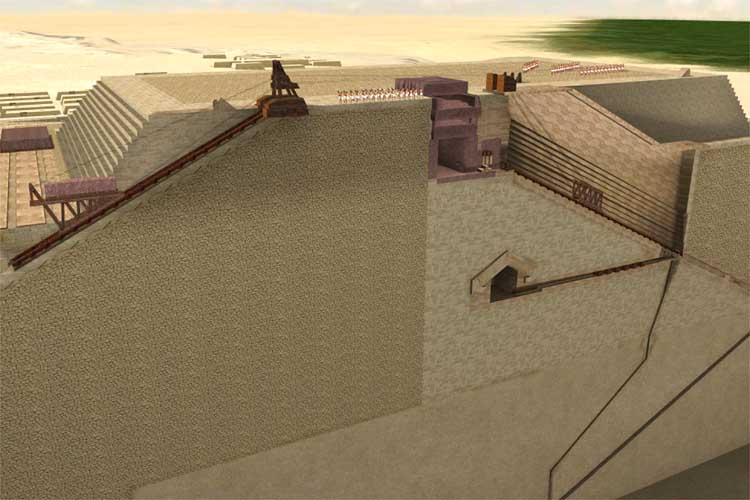

By Michael A. Veegh, P.E. © 2007 - All rights reserved We have all seen the pictures. Huge ramps running up the side of the pyramid. Or a winding ramp on the outside or, as recently proposed, a winding ramp on the inside of the pyramid structure. All in an effort to create a gentle slope for those bronzed Egyptians to pull their huge blocks of stone to the top of construction. The ramps are lubricated with mud to reduce friction, or the blocks are on rolling logs for the same reason. We marvel at these monumental efforts and the incredible hard work involved in moving and erecting the thousands and thousands of building blocks that make up the Great Pyramid. See pictures below. |

| Pictures by Dassault Systemes | |

| No one knows for sure how Hemiunu, the Pharaoh's Contractor, built the Great Pyramid, but here is a suggestion, using the means of the time. Basic Technologies. The first concept of a 'roller' might have come to anybody who saw a rock, a fruit or a log roll down a hill, or a round bread basket for that matter. I am guessing that this realization predates any Egyptian construction and we will assume this simple technology of a 'roller' was available at that time. Also, the archeological record shows that the pottery wheel first appeared in Egypt around the time the Great Pyramid was built. We can tell this by looking at the clay artifacts and how they change from being hand-formed to near perfect figures of revolution. Add to that the rope, from leather or some form of fiber, some copper tools and some basic carpentry skills and we have all the basic ingredients we need for erecting huge stone blocks to great heights. Brain vs. Brawn. The prevailing concepts mostly revolve around heavy objects being pulled up gently sloping ramps, with dozens of workers pulling on ropes to overcome gravity and friction. That is a strikingly inefficient use of human capability once the door is opened for an altogether different approach. What if all the workers took stairs to the top level of the pyramid-in-progress and then rode an 'elevator' back down? Every time a worker returned to ground level, a simple mechanism of rope, pulley and frame could raise a weight to the top of the pyramid at the same time. This weight would be less than the weight of the worker, because of inefficiencies in the mechanism and because of the need for a net driving force. Half the worker's weight might be a reasonable number. Let's assume a typical worker weighs 160lbs (72kg). Would you rather carry or drag 80lbs (36kg) to the top of the pyramid and then walk back down, or would you prefer to walk up the stairs with nothing but the clothes on your back and then take an elevator back down? The net result would be the same: 80 lbs have been brought to the top of the pyramid. Clearly, walking up empty-handed and riding the elevator down sounds more appealing. Of course, those who feel up to it can carry material on the way up, to improve the efficiency of the operation. The crux of the matter. Use the worker's potential energy (weight at a height) rather than the energy in his arms and legs to do work. Historically, we are better hikers than mules. Anybody can contribute to the project, men, women and children. This effectively doubles the size of the potential work force. We now have two options: Option 1 Each worker can raise 80lbs by going down the elevator. So 63 workers can raise 63 x 80lbs / 2000 = 2.52 tons or just about one typical block. This is the more efficient solution as measured by the number of trips.Once this mental step is made, to view the whole process as a 'discretization' of the load to be raised, any weight can be lifted by cumulative effort over a period of time. When looked at in this way, building and removing large external ramps is a huge waste of time and effort. Basically, the energy required to erect the pyramid is the energy required to raise the mass of the entire pyramid from ground level to its center of gravity, plus some allowances for inefficiencies.

Essentially, we are dividing the workforce into a small pool of skilled construction people (engineers, surveyors and whip-crackers) and a much larger pool of unskilled "hikers", acting as human power generators and batteries. Once the project is seen as an energy problem, having any worker walk back down the pyramid, and thereby waste his hard-earned potential energy, is an inexcusable engineering mistake. His potential energy should be transferred to a building block instead. Keep in mind that anywhere from 20,000 to 100,000 people were supposedly involved in this project, not all erecting blocks of course. Option 2 Having 63 people ride down an elevator all at once to raise one block is quite risky. Therefore, as a second option, workers can ride down in smaller groups or even individually to raise smaller loads. These smaller loads, once on top, can be used to raise one large ( 2.5 ton) block, without exposing 63 people to one big hazardous lift. But, the efficiency of the operation suffers. If the workers bring up smaller stones first with which to raise one large block, then we lose 50% of the available potential energy twice to friction in the elevator. Therefore, a total of 126 trips to the top would be required. That would double the project cost and duration, which is now directly a function of the friction losses in the elevator. Notice how important the friction in the system has become. If ever there was a pressing need for improved technology, this was the time. Cut the friction in half and bring the project time and cost down by a similar amount. The Elevator. Perhaps the simplest form of elevator (energy-exchanger) would be a rope thrown over a log supported by two A-frames, with a basket suspended on each side of the log. Friction between the rope and the log is a problem. Add some olive oil or animal fat for lubrication. Better yet, wrap the log with a copper strip, then add the lubricant. However, the rope keeps soaking up the lubricant in large quantities, so add a second copper strip over the first one, connect its ends and apply lubricant between the first and second strip. The rope stays clean and the friction is much less. The first friction bearing is born and the wheel and sheave are not far behind. If we accept the presence of a form of wheel in this society, as supported by the pottery artifacts from that time, then a fairly efficient elevator would be possible. Now add to that some rollers, again in the form of logs, and the large stone blocks can be moved into the pyramid horizontally, below the elevator, and then raised to the current construction level. Going one step further, by adding a second sheave at the bottom of the elevator, the elevator can also be used for dragging the blocks horizontally into the pyramid. History records the following. Hemiunu "invents" the human rock-elevator, gets the job done early and below budget and becomes the rock-star builder of his time. CTE Egypt is never mentioned. | |